PiezoWalk principle shows advantages for Monochromator crystal fine adjustment

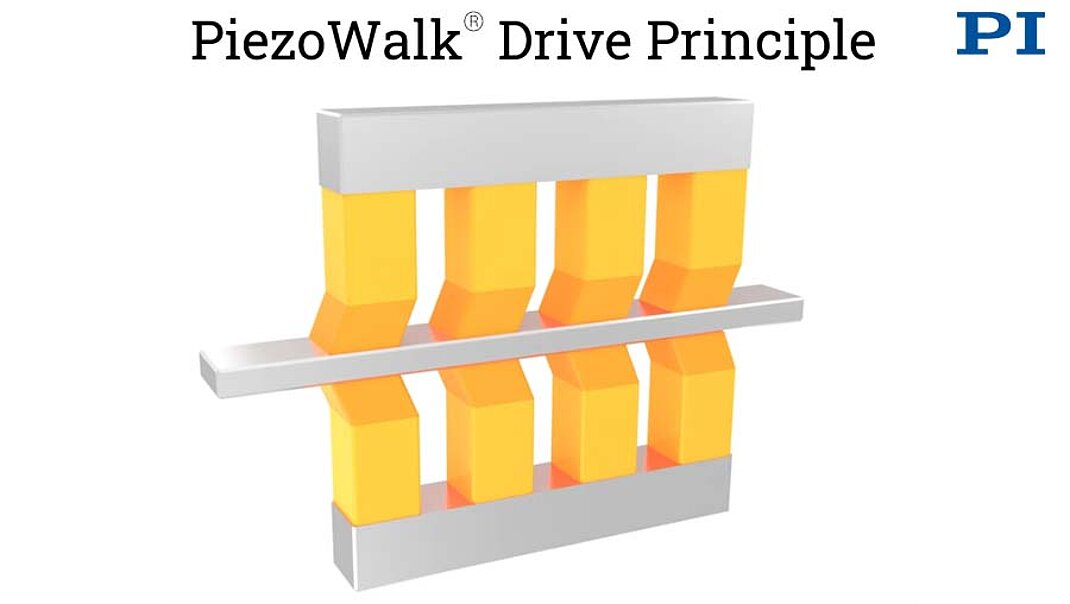

Piezo-based mechanisms have long been used in precision scientific instruments for precision motion generation. Previously, the limited motion characteristics of simple piezo actuators often made the use of a dual stage coarse/fine approach necessary. A novel approach based on a long-travel PiezoWalk drive shows promise in metrology and X-ray spectroscopy applications.

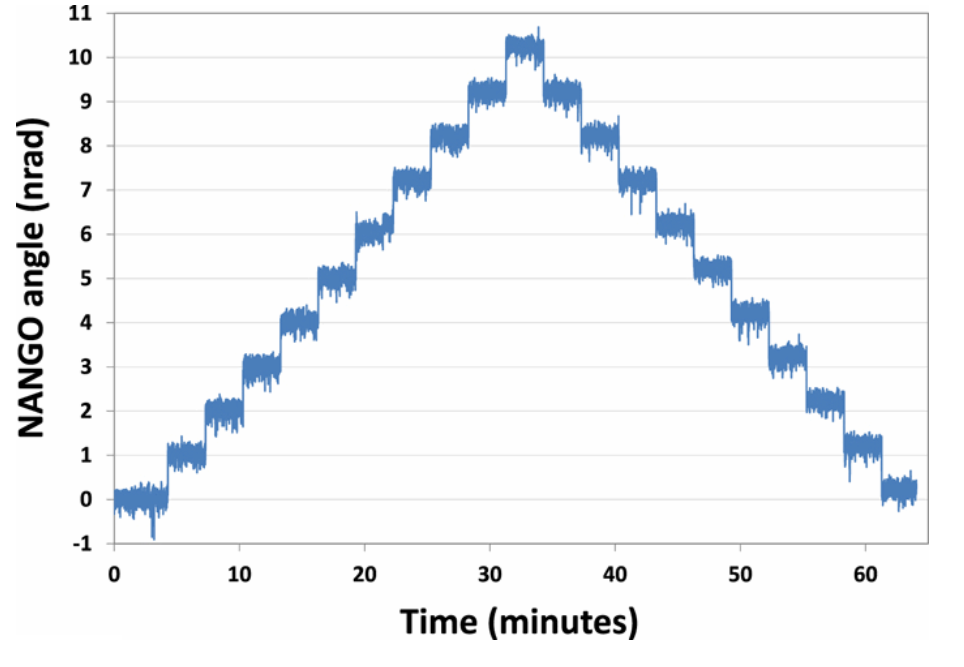

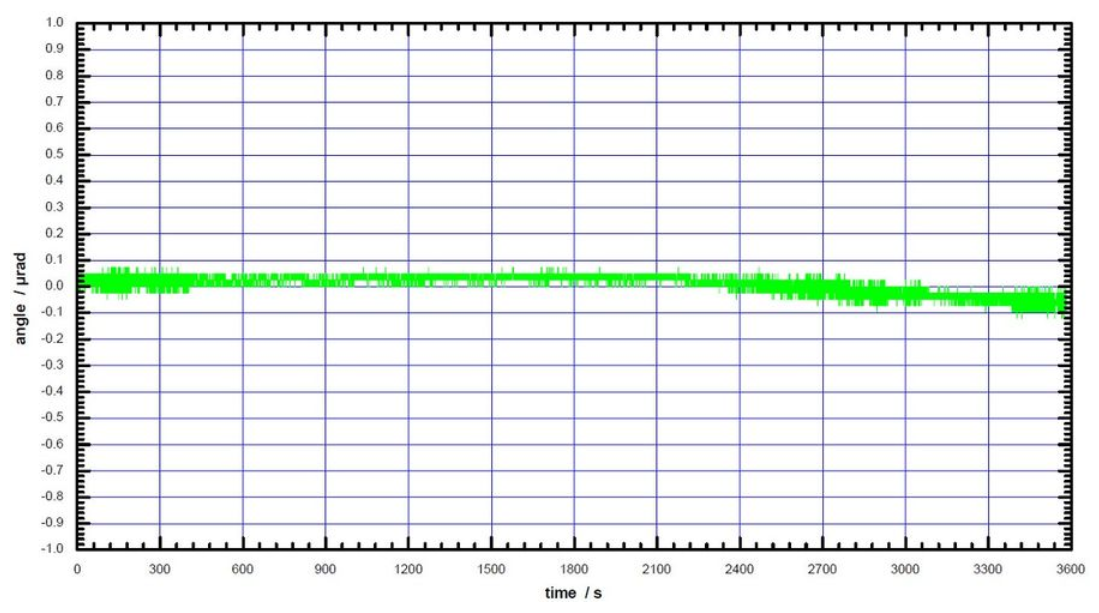

While PI NEXLINE closed-loop drives have already shown their capabilities to provide 1 nanoradian resolution over 7 milli-radians, with output stability of 0.3 nrad rms at the UK Diamond Light Source’s nano-angle generator (Diamond-NANGO), a new application at the ESRF is also quite remarkable.

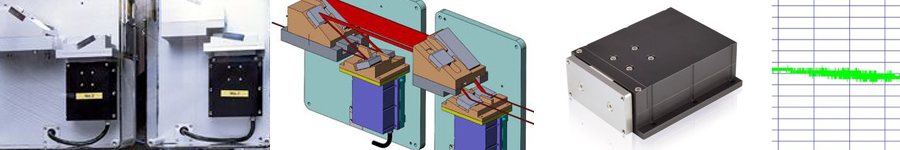

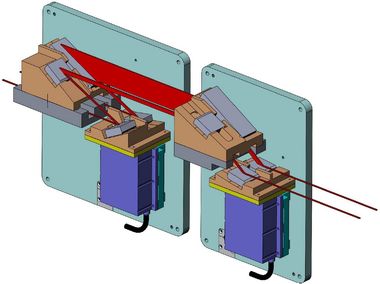

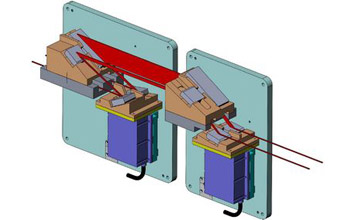

The ID18 beamline at the ESRF (European Synchrotron Radiation Facility) in Grenoble, France is employing these novel piezo-mechanisms to manipulate the position of the crystals in a double monochromator for inelastic X‑ray scattering.

The application demands resolution and repeatability of better than 100 nano-radians for both the Bragg angle and tilt angle of the crystal.

The double-crystal monochromator is used to examine phonon excitation in solids. Two monochromators select the desired wavelengths with an energy resolution up to 0.5 meV.

Each of the monochromators consists of four independent crystals arranged in pairs. The first pair collimates the beam, while the second pair selects the required energy. The full width at half maximum of the respective rocking curves is only a few microradians. To operate at the maximum intensity, the relative angle of the crystals to each other must be set to 0.5 µrad or better in both pairs.

Also, during a test series, scientists often need to quickly preselect samples with 2 meV resolution for more detailed tests at a very high energy resolution of 0.5 meV. This requires fast exchange of the monochromators with precise readjustment of the Bragg angle and the tilt angle of all four crystals.

To adjust the Bragg angle and the tilt angle of the crystals, they must be moved and positioned with high precision. Excellent long‑term stability and repeatability are also essential, while the space available for the positioning systems is very limited.

Positioning stages based on PiezoWalk drive technology show a number of advantages over conventional drive mechanisms. The closed-loop, self-clamping design provides the long-term stability required and the piezo effect delivers the resolution. Capacitive position feedback is used to close the loop with the motion controller. Long‑term repeatability of well under 0.1 µrad is achieved while the volume of the positioning stage is 95x78x32mm remains extremely compact.

NEXLINE piezo drives were originally developed for the semiconductor industry with extreme reliability and stability in mind. The technology is very mature and was selected for a Technology Innovation Showcase award by SEMI in 2005.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy