Optical Delay Line Stages – How to Choose the Right One?

Turning Nanometers into Femtoseconds and Attoseconds

Deep in the hallowed halls of the Paris observatory in the late 17th Century, a paradigm shift was underway. The speed of light conjectured by luminaries such as Descartes and Aristotle as infinite and instantaneous was empirically showing delays. The revelatory observation of eclipses of the Jovian Moon, Io, had provided a basis for what would become the first practical measurement of the speed of light using an optical delay from a variable path length. Today, very precise path length control in optical delay lines are critical to techniques in transient absorption spectroscopy (using pump-probe), Fourier Transform Infrared Spectroscopy (FTIR), and many other applications.

Why Minute Time Increments are Critical

In time-resolved spectroscopy, dynamic processes in materials and chemical compounds can be studied precisely. With the help of ultra-short pulse lasers, changes can be made visible, with time scales down to the attosecond range. The calculation below shows that a 10nm step in a free space delay line adds a delay of ~.07 femtoseconds (delay in solid materials, such as optical fibers, depends on their optical properties). With this in mind, it becomes clear that in order to control a delay line in the Femtosecond and Attosecond range, nanopositioning capabilities are essential.

Optical Delay Line Basics – Distance and Time

In the below diagram, we show the basic operating principle of a free space optical delay line. Here, the path is shown at Position X (green path) and again after a small linear translation to Position X’ (purple path). Note the green path overlaps a portion of the purple path. Let’s use this simple diagram to calculate optical path length difference and corresponding optical delay:

1. X=A+B+C (green path length)

and

2. X’=A+A’+B+C’+C (purple path length)

And path length difference is given by:

3. X’-X=A+A’+B+C’+C – (A+B+C)=A-A+B-B+C-C + A’ + C’ = A’+C’ (but A’=C’, the incremental motion step)

We then obtain:

4. X’-X=2A’

And in the time domain the optical delay is given by:

5. t= 2A’/c (where c is the speed of light)

In simple terms, this shows the direct importance of Minimum Incremental Motion (MIM) capability in the chosen linear translation stage that drives the optical delay in terms of temporal delay resolution. MIM is a standardized motion term that identifies the smallest consistent and reliable step that can be made with the stage.

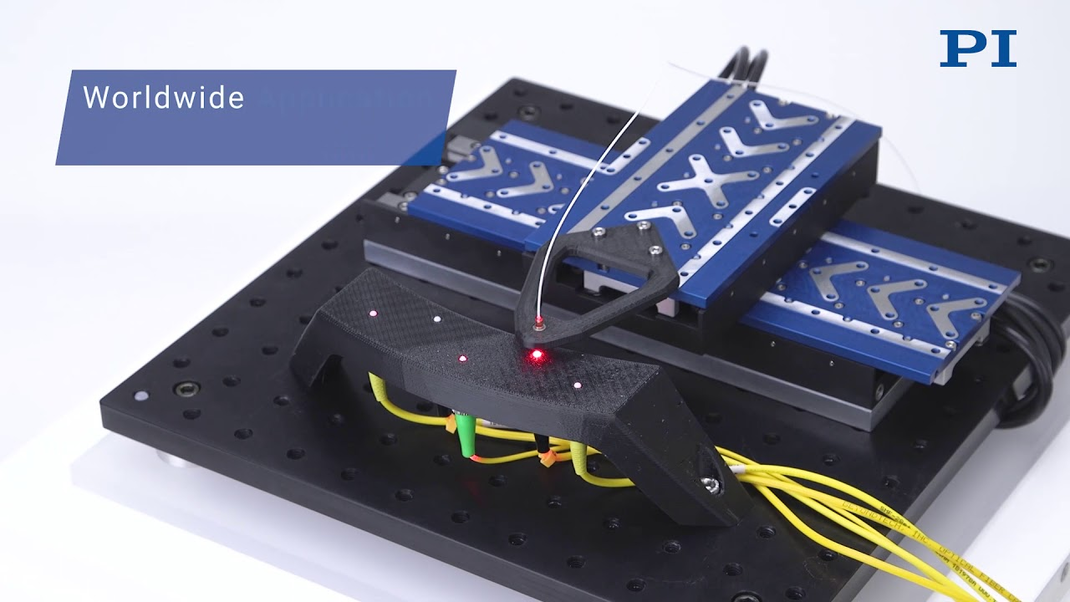

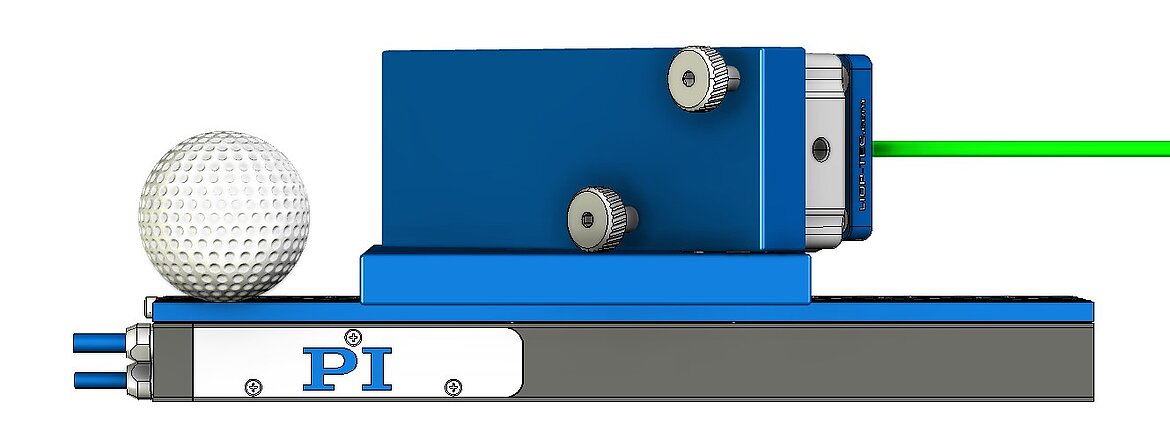

V-508 Series of Direct Drive Linear Translation Stages for Optical Delay Line Applications

The very fundamental influence of minimum incremental motion on Optical Delay Line time resolution makes it a guiding specification in PI motion solutions across a number of spectroscopy/microscopy and interferometry applications. In optical delay line applications, the first solution often considered is the V-508 Series of Linear Motor Stages. The direct-drive design, combined with the direct metrology linear encoder eliminate drive train errors such as backlash, play and non-linearities that are often found in screw-drive type linear stages, stepper motors or geared motors.

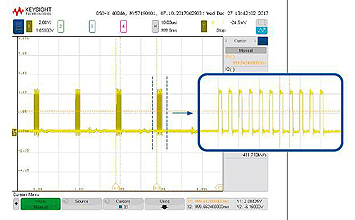

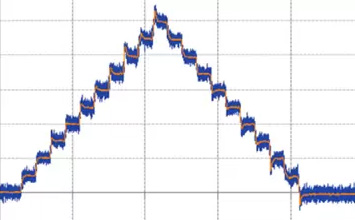

The V-508 Series of direct-drive precision linear motor stages provide an ideal platform for integration in optical delay lines combining PI proprietary nanopositioning technologies to achieve sub-nanometer resolution and single nanometer MIM.

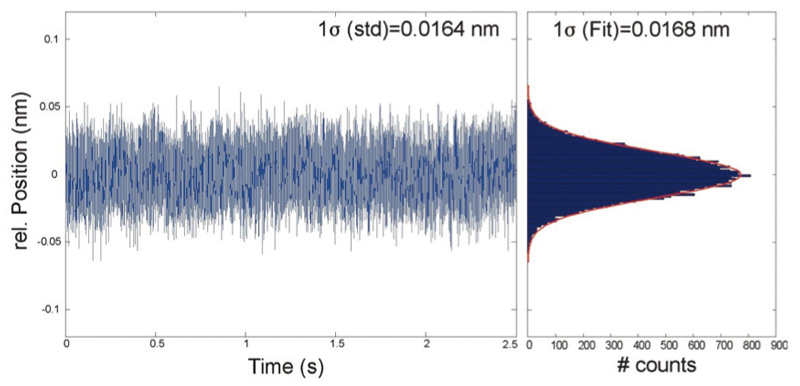

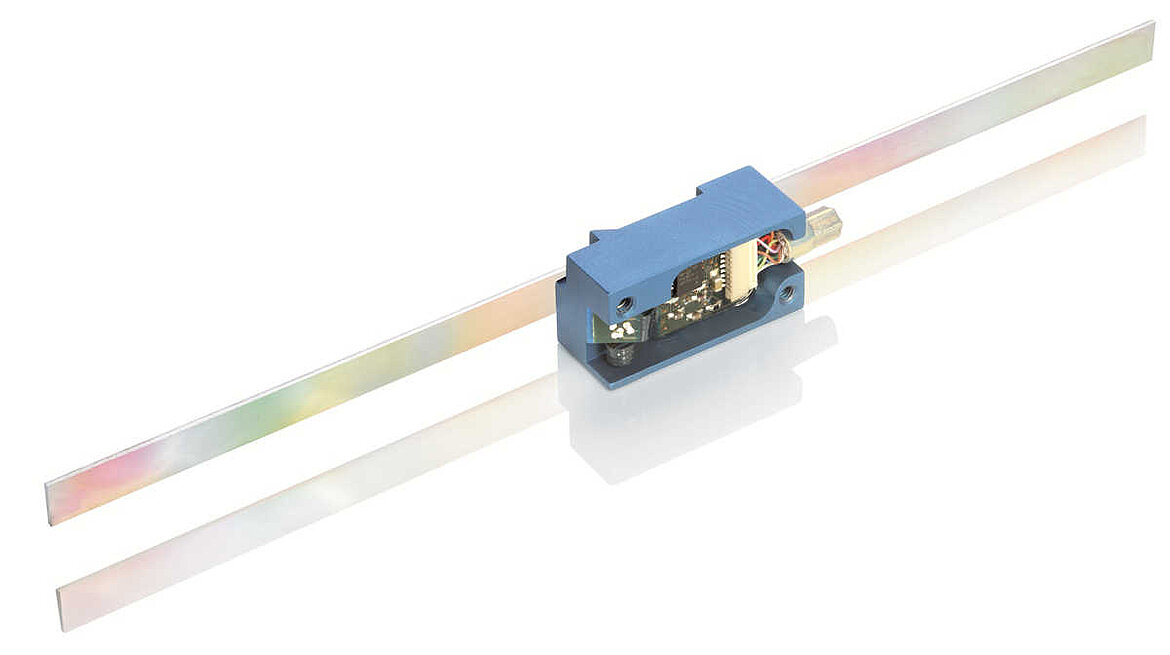

Ultra-High Resolution Feedback using PIOne Direct Metrology Linear Encoders

PIOne interferometric linear encoder technology offers ultra-high resolution position feedback at the moving platform. This direct metrology sub-nm resolution measurement provides superior performance along multiple metrics including: MIM, repeatability, accuracy, and position stability.

20pm Resolution: In linear incremental encoders, the resolution, i.e., the smallest measurable displacement the sensor head can discern along the scale, is highly dependent on the pitch (signal period) of the scale, the electronic signal interpolation factor, and electronic noise level. The lower the noise, the higher the possible interpolation can be set without losing performance, yet there are physical limitations and the best way to achieve higher resolution is a smaller signal period. The PIOne sensor can achieve better than 20 picometer resolution, based on its extremely short signal period of 0.5 µm and its advanced signal processing circuits – it allows 4000X interpolation without noise limitations.

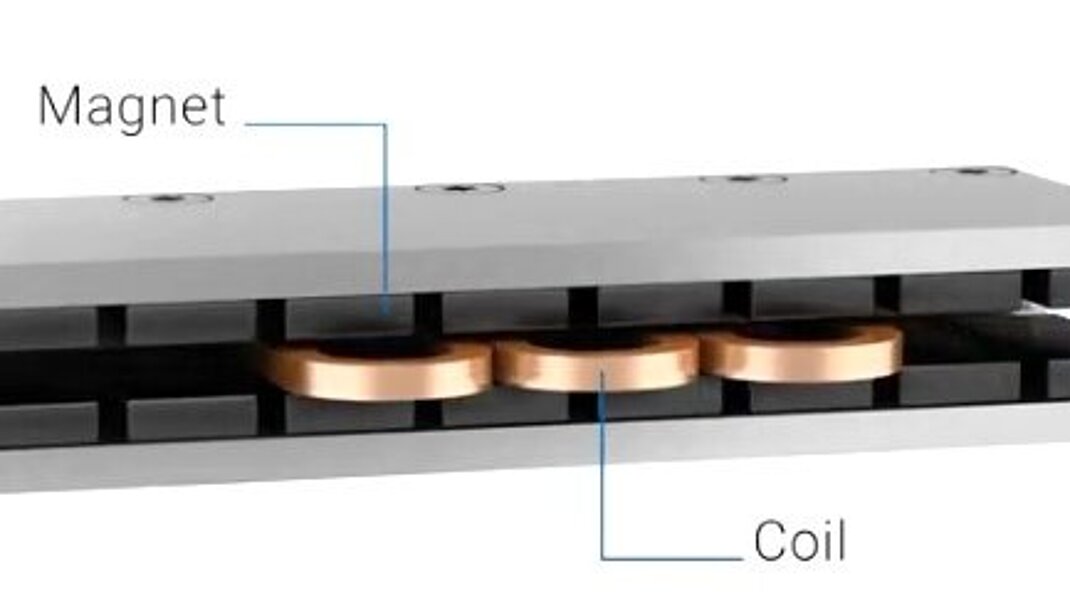

Center Driven Ironless Linear Motor and Precision Crossed Roller Bearings

Using compact, center driven ironless linear motors, V-508 offers dynamically responsive, smooth, ripple free nanopositioning capabilities without any inherent motor cogging characteristics that limit motion performance. These properties are supported by hardened steel crossed roller bearings with precision ground anti-friction guideways. The finely machined surfaces have a positive effect on friction characteristics minimizing stiction to enable 1nm MIM motion. Despite the high velocity these linear motors are capable of, they also provide excellent in position stability.

Compact Design for Effortless Integration

The V-508 uses an innovative design to achieve extreme compactness and low-profile, while integrating oversize bearings with extended operating life at rated load, ideal for cycled motions.

Low Profile, Non-Interfering Cable Exit

The static cable exit and extreme low profile of the V-508 linear translation stage supports easy integration with minimal impact to optical path layout.

Key Optical Delay Line Specifications of the V-508 Translation Stage Family

V-508 Optical Delay Line Specifications | |||

Model | V-508.251020 | V-508.651020 | V-508.951020 |

Travel | 80 mm | 170 mm | 250 mm |

Encoder Resolution* | 0.2 nm | 0.2 nm | 0.2 nm |

MIM | 1 nm | 1 nm | 1 nm |

Bi-Directional Repeatability | ±0.05 µm | ±0.05 µm | ±0.05 µm |

Max Velocity | 600 mm/s | 600 mm/s | 600 mm/s |

Minimum Optical Delay | 0.007 fs | 0.007 fs | 0.007 fs |

Maximum Optical Delay | 530 ps | 1134 ps | 1668 ps |

Pitch | ±100 µrad | ± 200 µrad | ± 300 µrad |

*interpolated

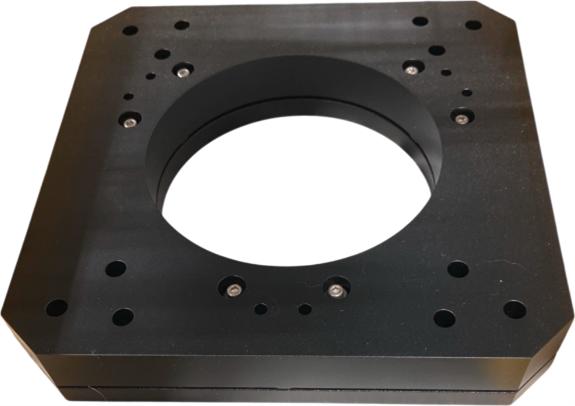

Air Bearing Delay Lines: Introduction and Background

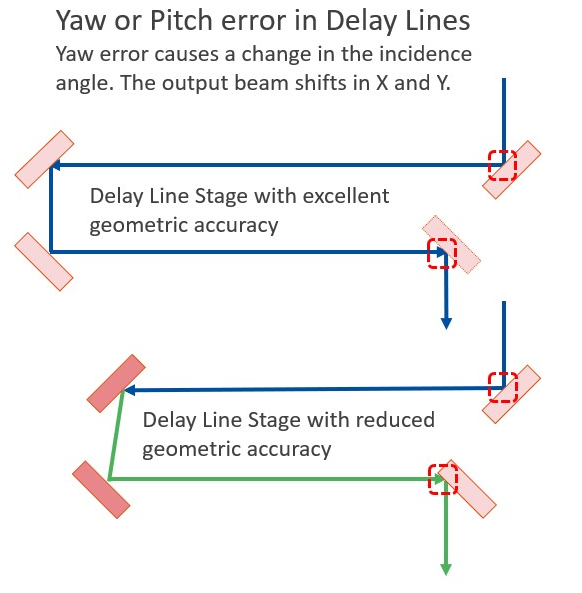

Delay lines have traditionally been based on low-cost, mechanical bearing linear stages and controllers. However, limitations of geometric performance have an effect on the accuracy of the measured results and velocity constraints may limit the number of experiments per time slot.

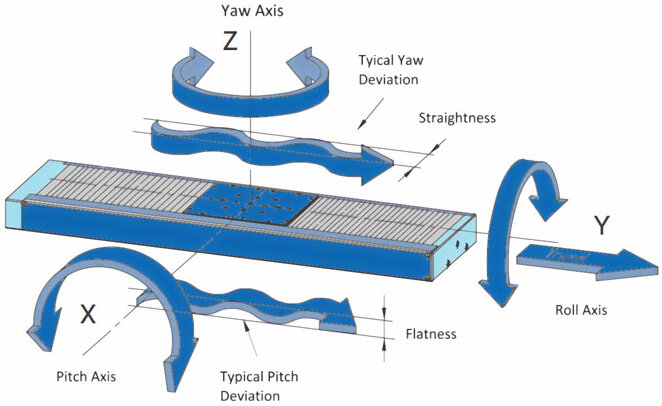

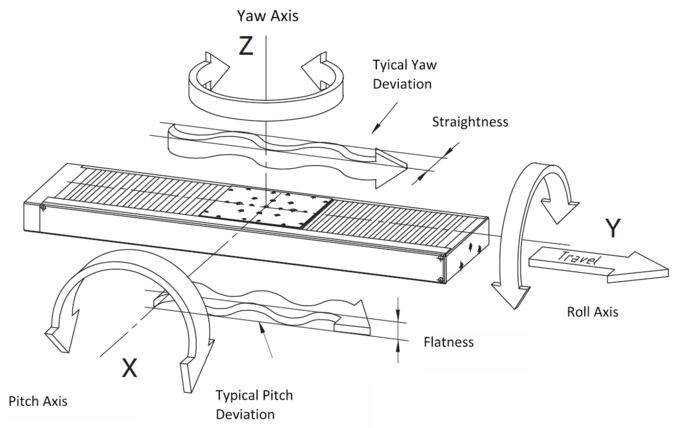

Straightness and flatness errors cause an excursion from the beam path, shifting the output beam in X and Y. Yaw errors cause a change in the incidence angle, also shifting the output beam in X and Y.

Air bearings have substantial advantages over the mechanical bearing stages. Air bearings have significantly lower pitch/yaw angular errors and almost perfect straightness and flatness. This means that when pumping and probing at various delays, the beam stays at or very close to the Region or Point of Interest. Furthermore, higher velocities and faster settling enable gathering ofmore data and researchers can now conduct up to 2X more experiments, important with limited beam line time.

| Air Bearing Delay Line Stages, Specifications | ||||

Model | ADL25 | ADL100 | ADL200 | ADL300 |

| Delay Range, nanoseconds | 0.16 | 0.7 | 1.3 | 2 |

| Travel, mm | 25mm | 100mm | 200mm | 300mm |

| Delay Resolution, fs (nm) | 0.035 (5) | 0.07 (10) | 0.07 (10) | 0.07 (10) |

| Max Speed, mm/s | 390 | 500 | 1000 | 1000 |

| Pitch, µrad | 80 | 10 | 10 | 17.5 |

Yaw, µrad | 15 | 10 | 10 | 17.5 |

| Flatness, µm | 0.25 | 0.5 | 0.75 | 1 |

| Straightness, µm | 0.05 | 0.5 | 0.75 | 1 |

Bi-directional Rep, µm | 0.1 | 0.1 | 0.1 | 0.1 |

Accuracy, µm | 0.2 | 0.5 | 0.5 | 0.5 |

Based on Stage Type | A-110.100A1 | A-110.100A1 | ||

Notes: *A-143 uses an absolute encoder. The A-811.CED05 high-precision motion controller, a 3m cable and power supply are included. LabView-based Software and A-805 air prep kit are available separately.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy